Search

ICNAP is a collaborative center where we come together to address and solve the challenges of digitalization

66

Projects

15

Services

49

Files

7

Topic Fields

70

Scientific Contributors

4

Institutes

To fully leverage the benefits of our resources, we invite you to become a member of our community. Membership provides you with exclusive access to all project results, allowing you to delve deeper into the world of ICNAP.

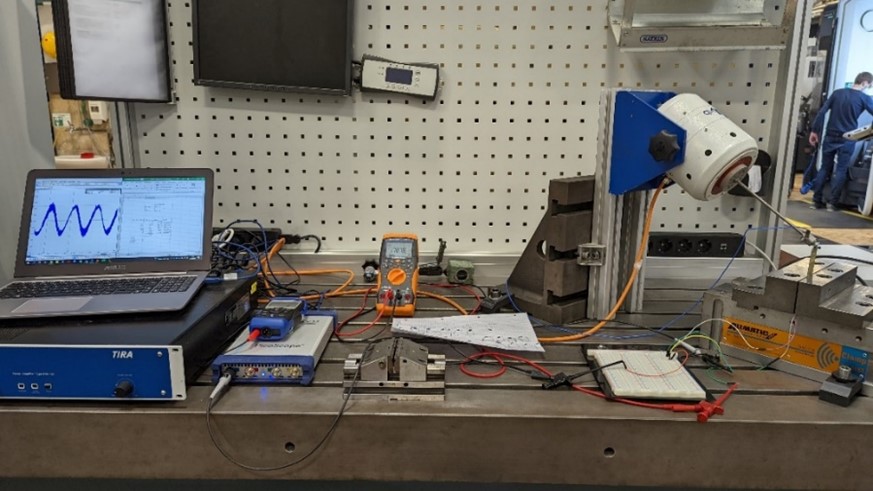

The study investigates energy harvesting as a power source for industrial wireless 5G sensor platforms, utilizing ambient sources like light, heat, and vibration. Energy harvesters (EH) from various manufacturers were tested, with a vibration EH from ReVibe producing a maximum of 200 mW at 51 Hz, while others ranged from less than 1 mW to 65 mW. Temperature EHs yielded the least power, at 0.37 mW with a 140°C temperature difference, but using heat sinks quintupled the output. Solar EHs generated 0.2 - 2 mW indoors. The 5G transceiver's energy consumption was between 1 - 1.8 W, indicating that current EH technology can only support autonomous 5G sensor operation with low transmission rates and an integrated battery. Future improvements in EH efficiency and 5G energy consumption are anticipated, making the findings relevant for a wide range of wireless sensor applications.

| Topic Fields | |

| Published | 2022 |

| Involved Institutes | |

| Project Type | ICNAP Research/Transfer Project |

| Responsibles |

Contact us to get in touch! With a membership, you’ll gain full access to all project information and updates.

The aim of the study is to investigate the use of energy harvesting for the energy supply of wireless (5G) sensor platforms in industry. Based on a market research on industrially applicable energy harvesters, various components and modules from different manufacturers were procured. Energy harvesting first requires an energy source provided by the process itself or from the environment. Typical energy sources are light, heat or vibration. The energy harvester (EH) converts these into electrical energy. A management board (e.g. from the manufacturer e-peas) ensures the optimized supply of energy to the sensor system. For each EH there is a predefined resistance that defines the maximum energy conversion, the so-called Maximum Power Point (MPP). In experimental tests, this was determined for different energy sources and manufacturer modules. The maximum energy outputs of the modules were then determined. A value of 200 mW at 51 Hz was achieved for the vibration EH from the company ReVibe. Other vibrations EHs provided values in the range of less than 1 mW to 65mW (module from the company Xidas). The temperature EHs achieve the lowest energy output in the range of 0.37 mW at 140 °C temperature difference (+ heat sink). The use of heat sinks on the EH increases the energy output by five times. Solar EHs produce indoor energy output in the range of 0.2 - 2 mW. Different light sources were considered (fluorescent tubes and LEDs). The energy consumption measurements for the 5G transceiver Quectel RM500Q resulted in values in the range of 1 - 1.8 W. Thus, energy-autonomous operation of a 5G sensor platform using EH is only possible at this point in time if the transmission rate is correspondingly low and a battery is integrated for energy storage. However, an increase in the performance of EH systems as well as an increase in the energy efficiency of 5G transmissions is foreseeable for the future. This study provides a first insight into the current performance of EH and how it can be used to power wireless sensor platforms. This applies across the board not only to 5G sensor platforms, but also to wireless sensor technology in general, so that the application is farreaching and the results are transferable.

© Fraunhofer 2025